There are typically five primary types of containment boom manufactured and deployed in the United States and Canada. We provide a brief description of each for the benefit of those not familiar with containment boom. All containment boom is sold in managable sections that can be joined end to end to form longer lengths. Boom manufacturers typically utlize universal connectors so that boom from different companies can be used in combination. In emergency deployments, containment boom can be strung continuously for miles.

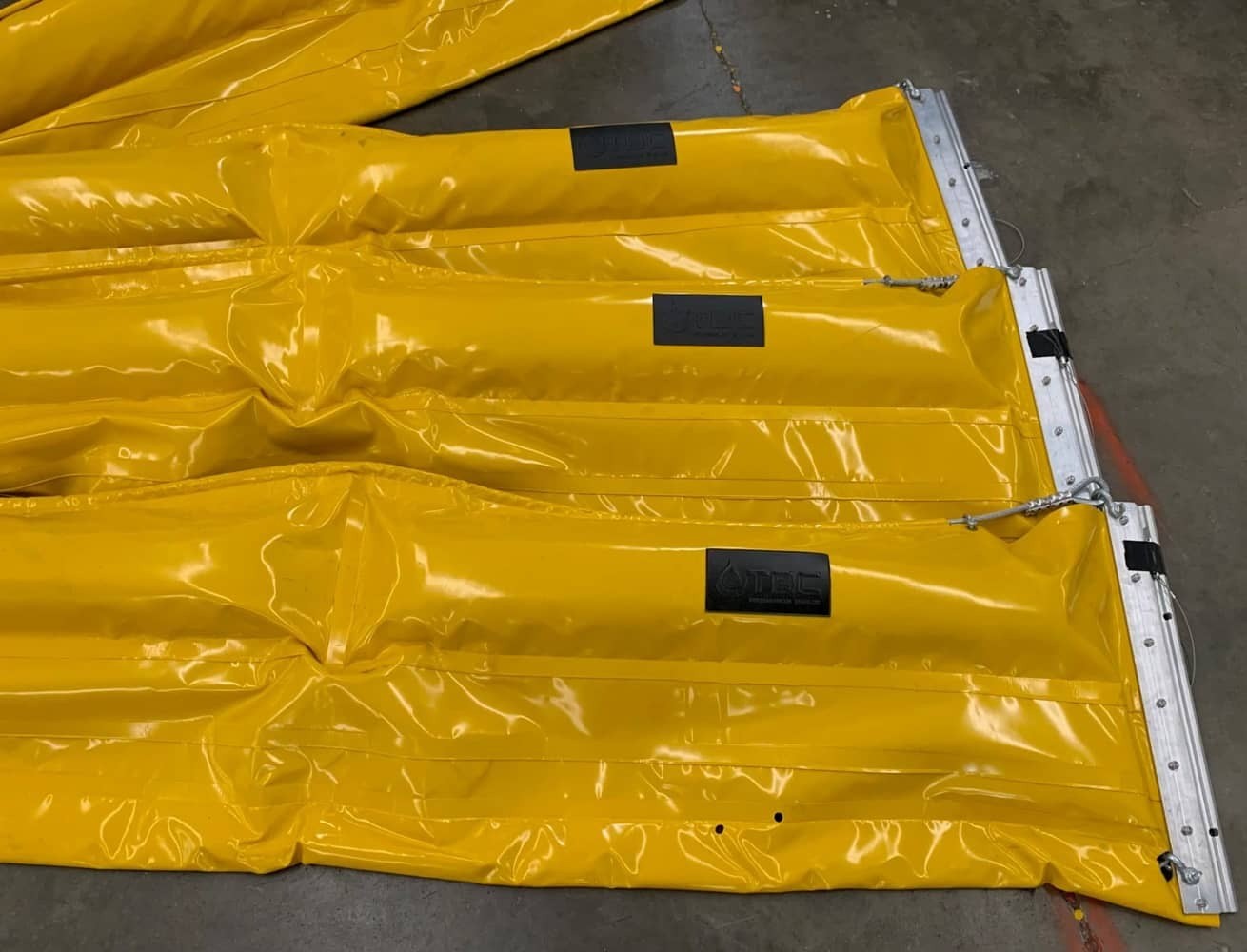

1 - Foam Filled Containment Boom

Also referred to as Conventional Boom, Contractor Boom, Standard Boom. This boom has flotation chambers filled with closed cell foam and sealed to provide the buoyancy needed to keep the boom afloat and provide the freeboard that contains the oil. These booms also feature a skirt that is suspended below the water to help with oil containment. This skirt provides the draft height. Tension cables and ballast chains provide strength and stability. Containment boom is light and can be quickly and easily deployed.