When a call comes in as the result of an active spill, office hours don't much matter. Texas Boom Company stands at the ready to equip companies to quickly and effectively respond to oil spills. The most recent example occurred when a leaking wellhead was identified in Tabbs Bay near Baytown, TX. The exact source of the leak was unknown, so each of the companies that potential own the wellhead responded quickly. TBC was asked to provide conventional oil spill containment boom and sorbents and responded by getting a trailer loaded in short order. Our company also worked to provide additional sorbent boom the following day and consulted on deployment as well. The goal at TBC is to have inventory at the ready for just such a need and to provide the knowledge needed to effectively deploy the products.

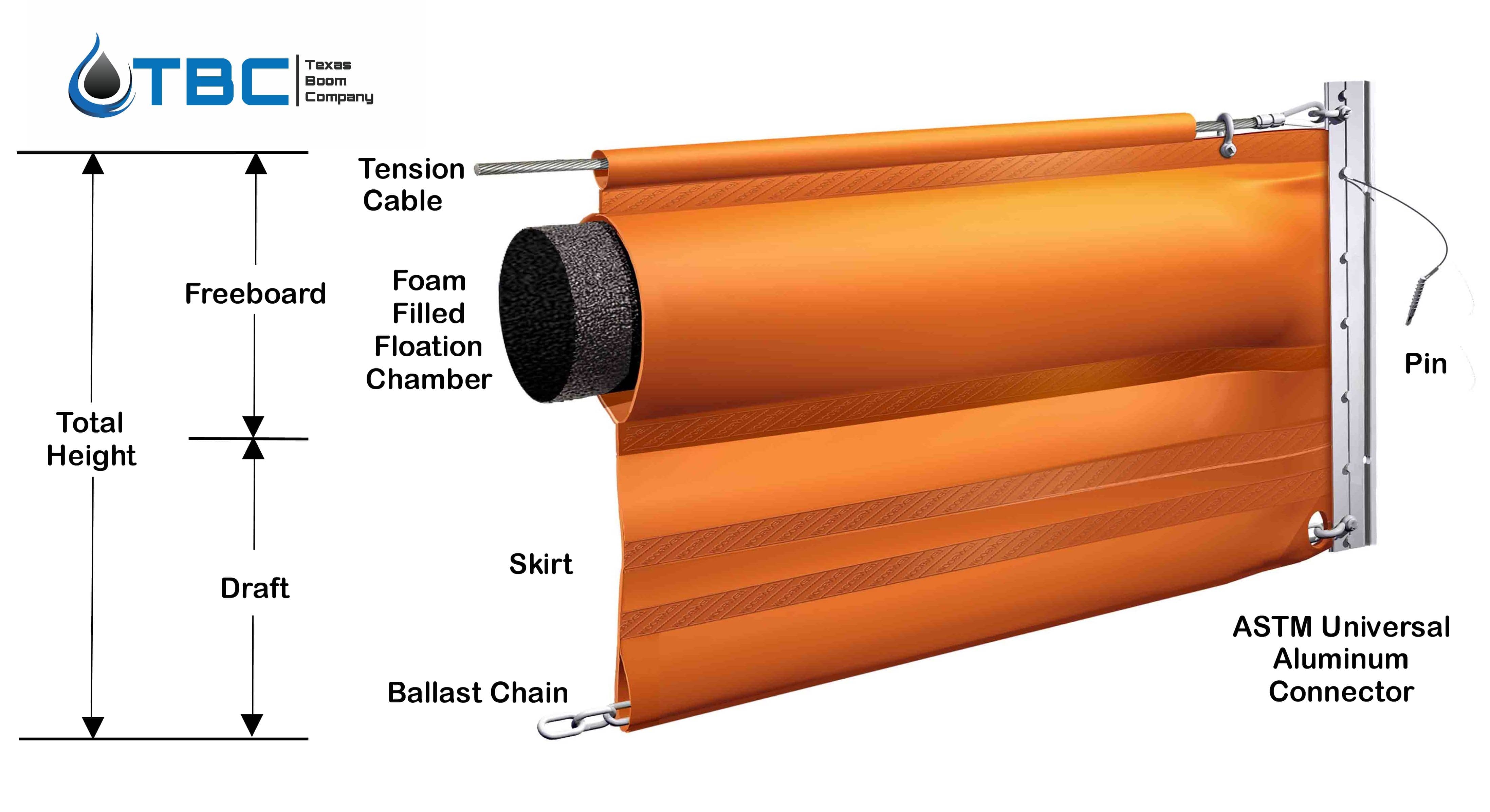

While we hate to hear of any spill, we take pride in knowing that our products are used to mitigate the damage that results from any spill. Containment boom keeps the oil from spreading. Sorbent boom adsorbs the oil without taking on the water. Oil skimmers collect the oil without intaking the water. These three primary components are all be used in conjunction to reduce the environmental impact until the oil can be recovered and the shoreline cleaned. It's not a perfect system, but it serves a tried and true means to lessen the damage caused by any spill.

Workboat sets a perimeter with Texas Boom Company's oil spill containment boom.