Texas Boom Company typically uses a 22 oz PVC fabric to construct our oil spill containment boom. This fabric offers a good balance between durability and cost. This weight fabric adheres well during the RF welding process that TBC utilizes for all seams. However, there are times when either a lighter fabric is prefered to reduce costs since the oil spill boom may be utilized for a shorter window of time. Other times, a heavier weight fabric is preferred to add longer life and greater durability if the oil spill containment boom is expected to be deployed and retrieved repeatedly over time.

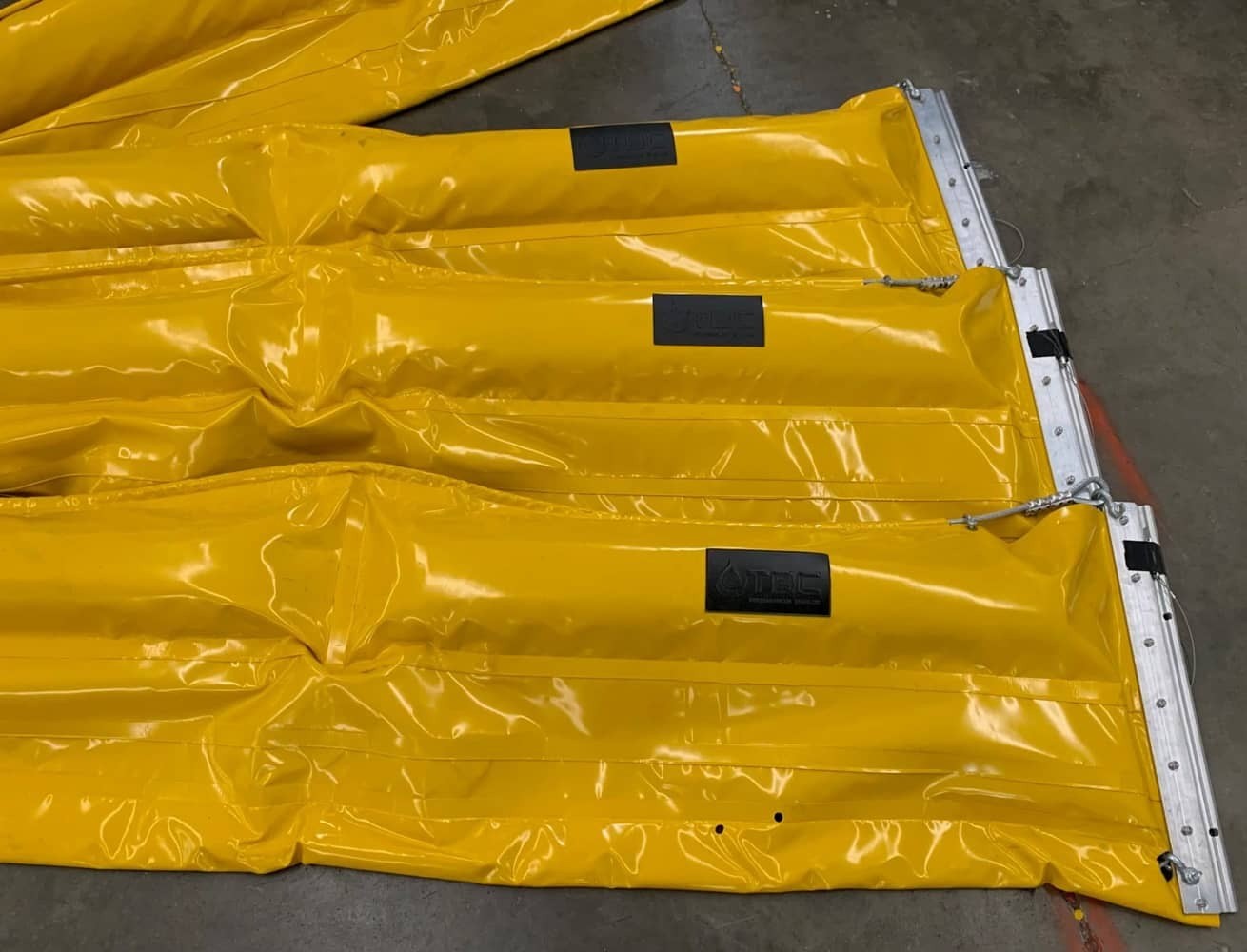

Shown above is a recent production run that utilized 28 oz PVC fabric. The customer needed the oil spill containment boom to be used repeatedly to conform with port requirements when their ships were docked. Other fabrics like Polyurethane are also options. Color is also a consideration with some customers. Permeability is a key requirement on some silt curtain skirts. We are always willing to consult with customers to choose the best fabric material and weight to meet their needs. TBC can manufacture oil spill containment boom, silt curtains,and collapsible fabric tanks to exact customer specifications.