On the early morning of September 8, the MV Golden Ray capsized off the coast of Brunswick, GA in St Simon Sound, approximately 80 miles south of Savannah. The exact cause of the accident has not been finally determined. Initially, four of the twenty-four individuals on board were trapped. They were subsequently rescued safely. However, the ongoing environmental hazards continue now over a month later.

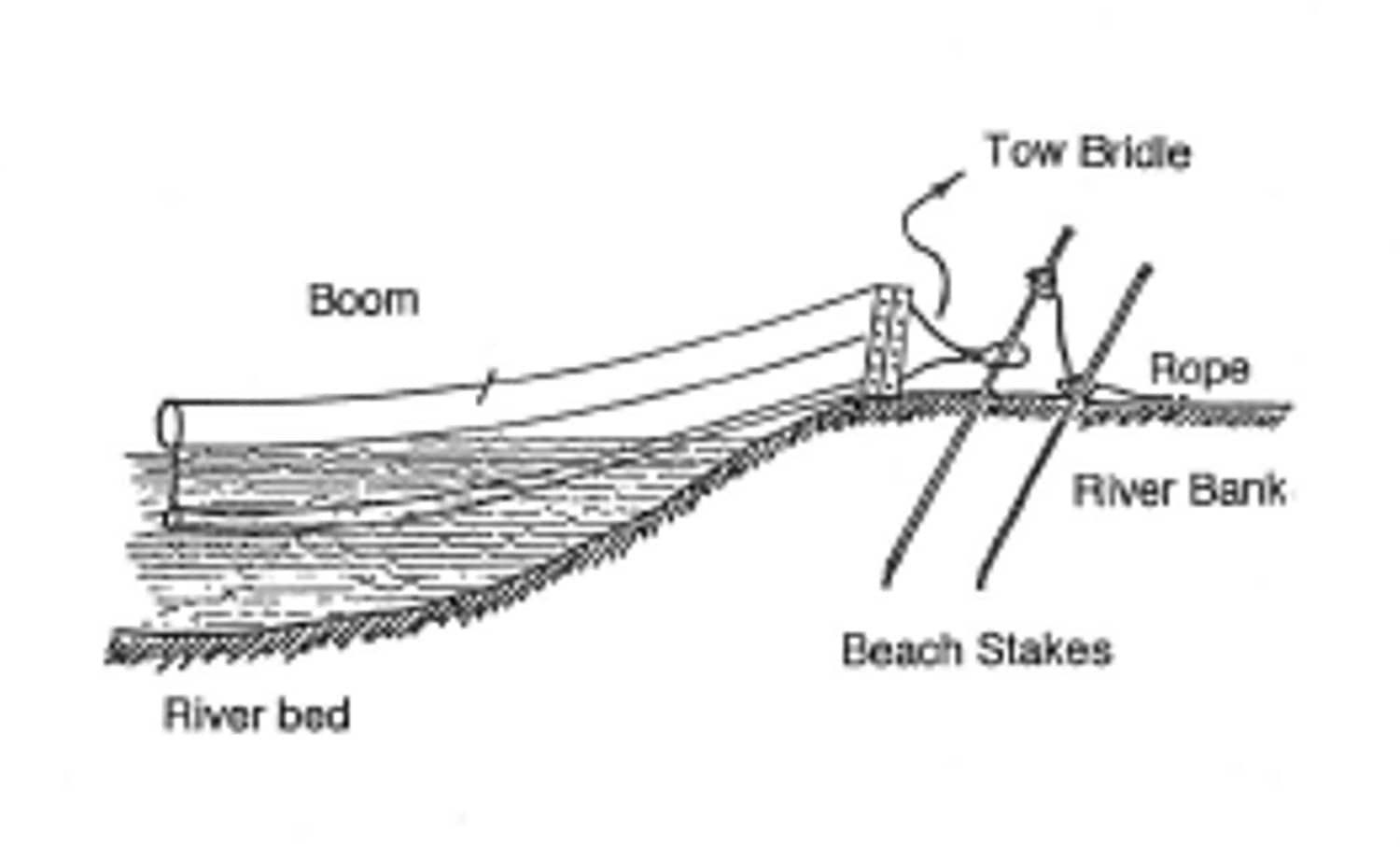

Fuel and oil continue to leak from the vessel. When the accident occurred, the ship contained roughly 300,000 gallons within its tanks. To date, 220,000 gallons have been successfully pumped off. Unfortunately, there have been ongoing oil slicks located in the area, as well as oil coating the plant life along shorelines. Thousands of feet of oil spill containment boom have been deployed in the area to control the spread of the hydrocarbons and protect the shorelines.

The US Coast Guard is leading the Unified Command, a joint recovery and salvage effort between the state of Georgia, the USCG, and the shipping company Hyundai Glovis’ contractor, Gallagher Marine Systems. Crews of up to 400 people and 70 vessels are participating in the clean-up and recovery effort.