In the world of environmental protection and sustainability, preserving the quality of our water bodies is of paramount importance. Turbidity curtains, also known as silt curtains or turbidity barriers, play a vital role in this mission. Texas Boom, a trusted provider of environmental solutions, offers a wide range of Turbidity Curtains that help control sediment and maintain the ecological integrity of our waterways. Let's explore the significance of these specialized barriers and the contributions of Texas Boom to this critical environmental endeavor.

The Importance of Water Quality

Water quality is a fundamental concern for ecological balance, human health, and various industrial activities. The presence of excessive sediment and suspended particles in water can disrupt aquatic ecosystems, hinder navigation, and create problems for water treatment facilities. As a result, controlling turbidity, or water cloudiness caused by sediment, is essential.

The Role of Turbidity Curtains

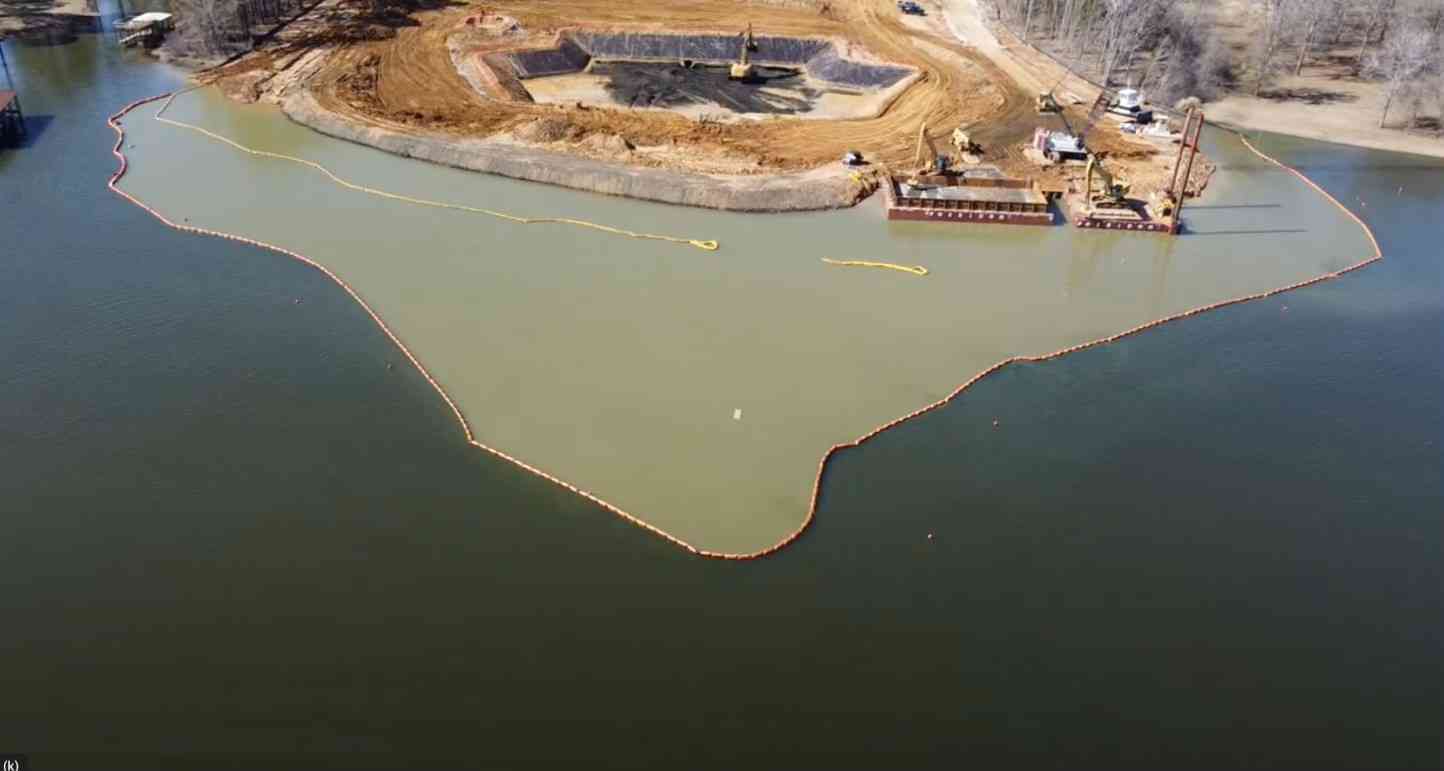

Turbidity Curtains are engineered to address the problem of sediment dispersion in water bodies. These curtains create a physical barrier that prevents sediments and particles from spreading beyond a specific area. Their primary functions are:

Turbidity Control: Turbidity curtains effectively reduce the movement of suspended sediments, preventing them from muddying surrounding waters.

Erosion Prevention: These barriers play a crucial role in protecting shorelines and underwater habitats from erosion caused by sediment runoff.

Environmental Preservation: By containing sediments, turbidity curtains help maintain the health and integrity of aquatic ecosystems, benefiting aquatic life and natural habitats.

Compliance with Regulations: Many industries are required by law to use turbidity curtains to prevent sediment contamination during construction, dredging, and other activities.

Texas Boom's Turbidity Curtains

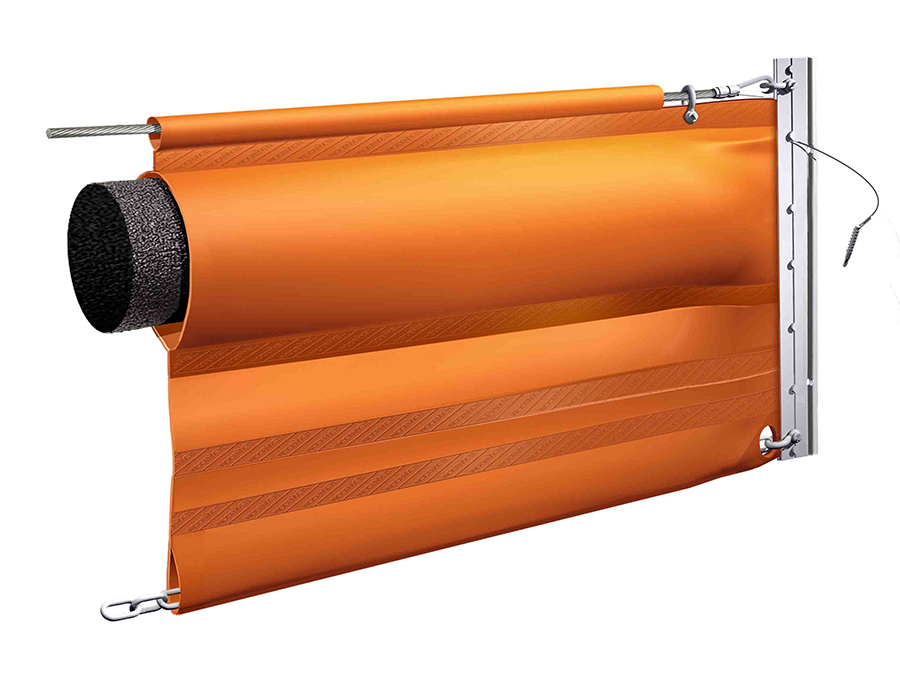

Texas Boom offers a comprehensive range of Turbidity Curtains designed to address various sediment control needs. These curtains are manufactured with top-quality materials and engineered for durability and effectiveness. Key features of Texas Boom's Turbidity Curtains include:

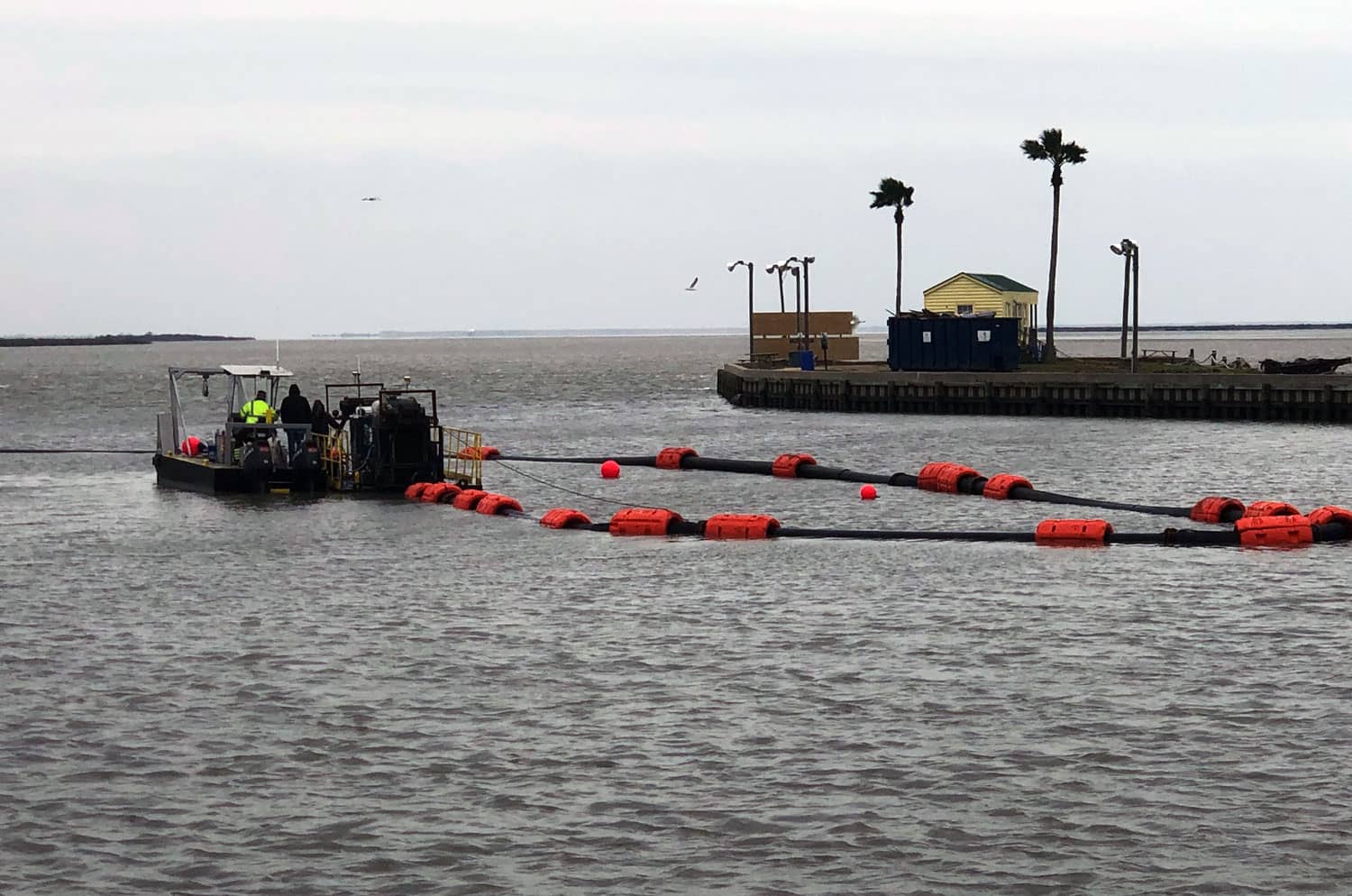

Floatation and Skirt Design: These curtains are equipped with floatation devices and a skirt that extends below the water's surface, ensuring optimal effectiveness in controlling sediment dispersion.

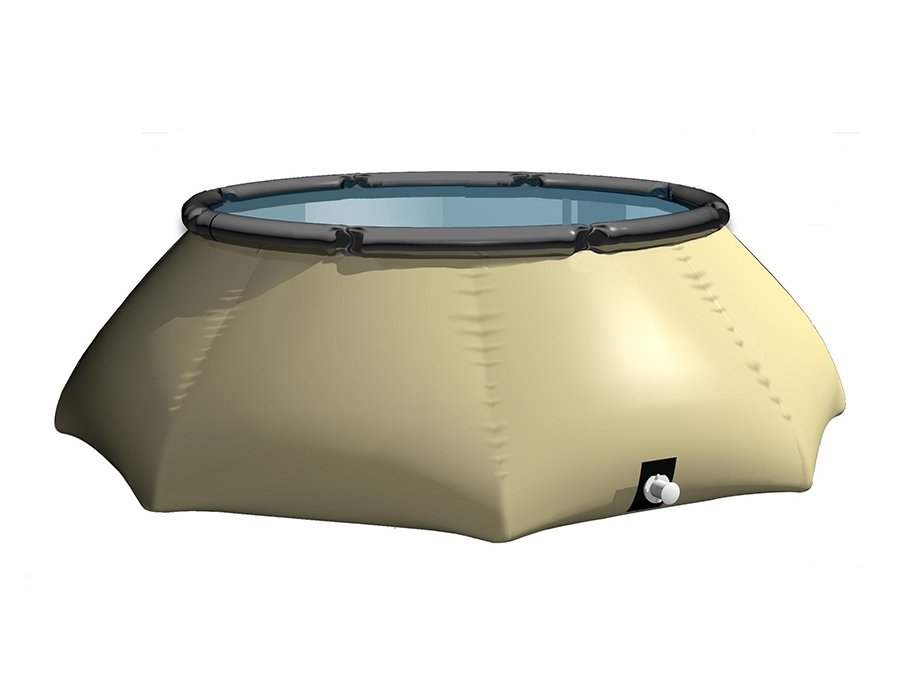

Customization: Texas Boom provides customization options to tailor turbidity curtains to specific project requirements, whether it's for construction, dredging, or environmental restoration.

Ease of Deployment: These curtains are designed for easy deployment and retrieval, saving time and labor costs.

Environmental Responsibility: Texas Boom's commitment to environmentally friendly solutions ensures that their turbidity curtains have minimal impact on aquatic ecosystems.

The Benefits of Using Turbidity Curtains

Erosion Control: Turbidity curtains effectively prevent shoreline erosion, protecting aquatic habitats and infrastructure.

Water Quality Preservation: By reducing turbidity, these curtains help maintain water clarity and quality, essential for aquatic life and overall ecosystem health.

Regulatory Compliance: Industries and organizations that deploy turbidity curtains remain compliant with environmental regulations, avoiding potential legal issues and fines.

Sustainable Practices: The use of turbidity curtains promotes responsible and sustainable practices in construction, dredging, and other industrial activities.

The role of Turbidity Curtains in preserving the quality and health of our water bodies cannot be overstated. Texas Boom's range of Turbidity Curtains offers tailored solutions for various industries and projects, ensuring that water quality and environmental conservation remain top priorities. By choosing Texas Boom's environmentally responsible products, industries and organizations contribute to the protection of our aquatic ecosystems while maintaining compliance with environmental regulations. Turbidity curtains from Texas Boom are not only barriers; they are shields of environmental protection and clarity for our precious waterways.