{unitegallery videos}

Request A Quote

Provide some details about your needs and receive a quote promptly.

{unitegallery videos}

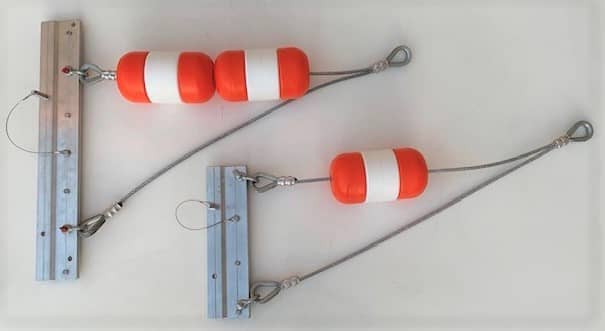

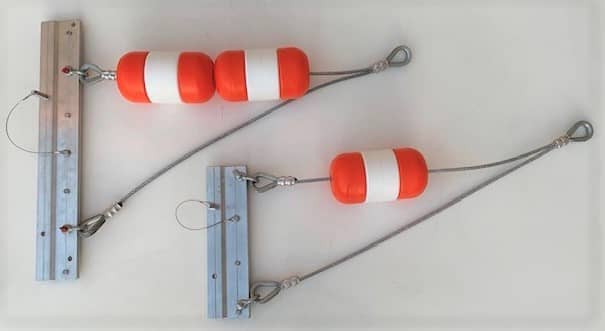

Figure 1 - Tow Bridles

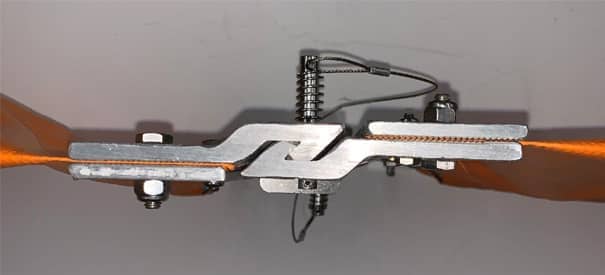

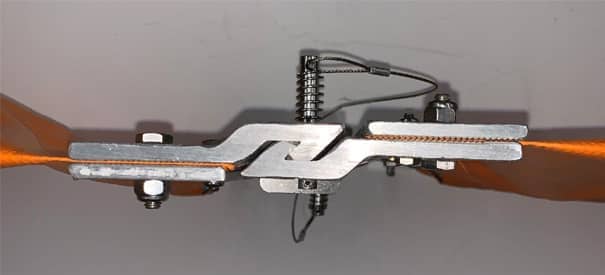

Figure 2 - End Connectors Secured with Toggle Pin

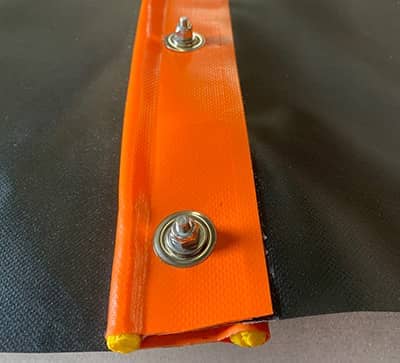

Figure 3 - Grommets Connected with Cable Zip Ties

Figure 4 - Grommets Connected with Stainless Nuts and Bolts

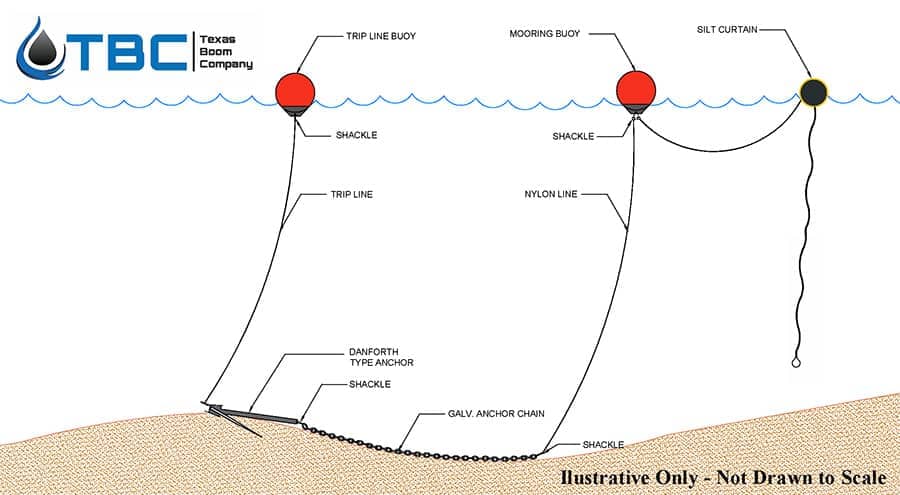

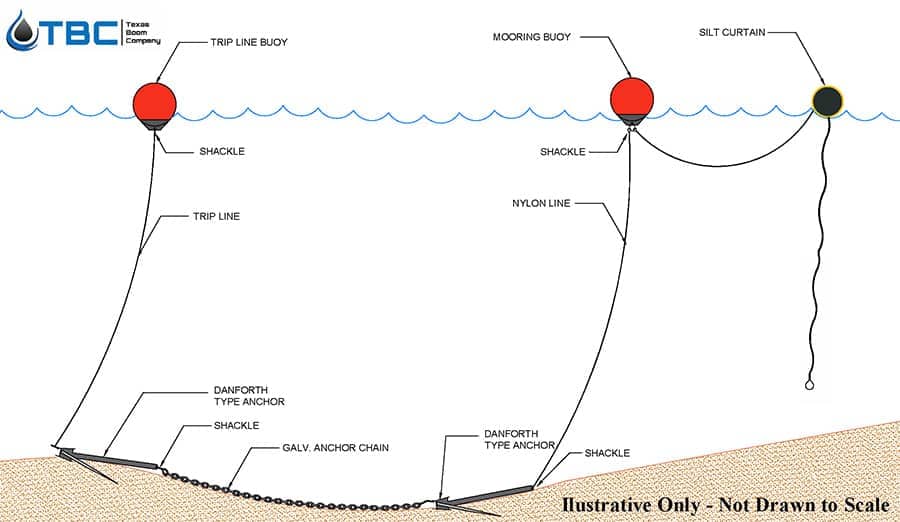

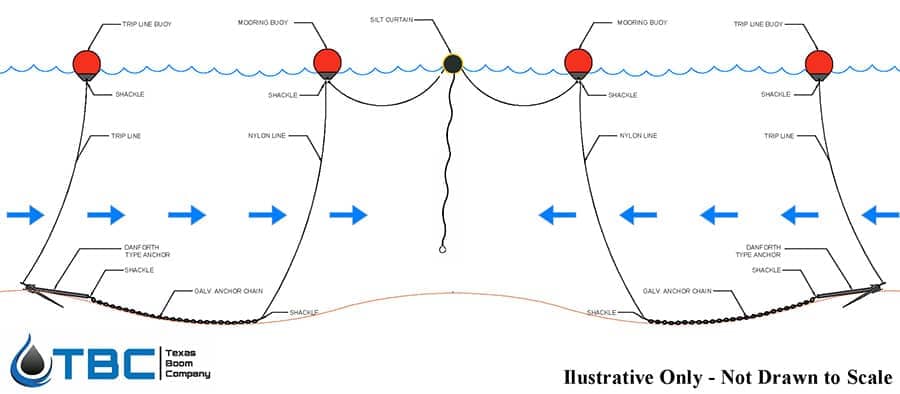

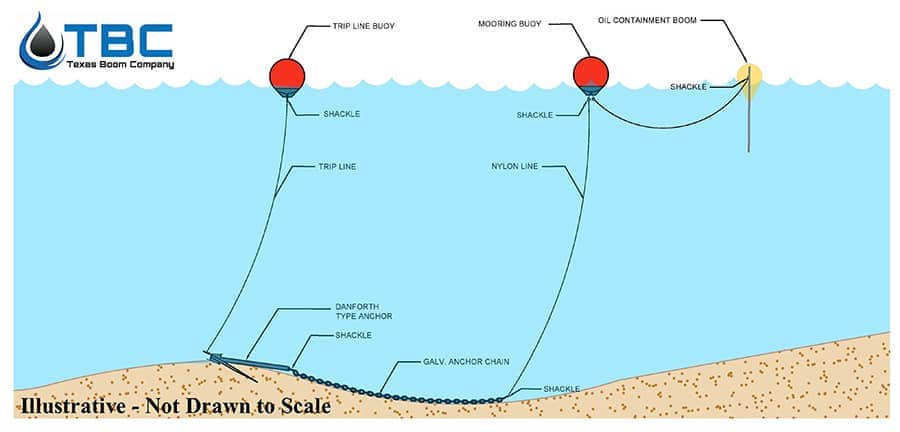

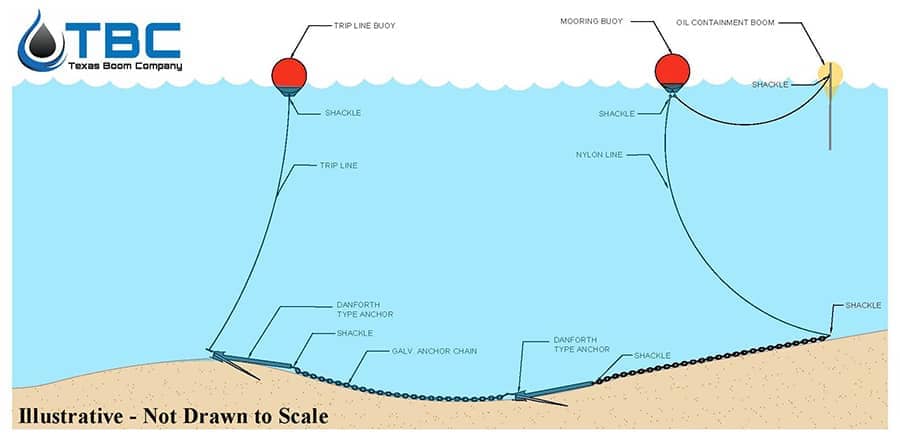

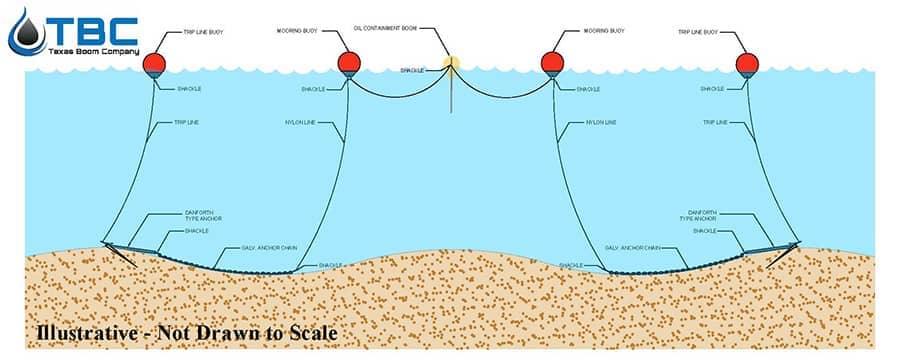

The next three diagrams below illustrate the components and arrangement of an effective anchoring system. The scenarios depicted include a simple single anchor layout for calm water deployment (Figure 5), a double anchor layout where current, tides, or winds may require additional holding strength (Figure 6), or a layout requiring anchors in both directions where tides and currents change directions (Figure 7).

Single Anchor Configuration for Each Anchor Point

Figure 5

Double Anchor Configuration for Each Anchor Point

Figure 6

Dual Direction Anchor Configuration for Each Anchor Point

Figure 7

The next three diagrams below illustrate the components and arrangement of an effective anchoring system. The scenarios depicted include a simple single anchor layout for calm water deployment, a double anchor layout where current, tides, or winds may require additional holding strength, or a layout requiring anchors in both directions where tides and currents change directions.

Single Anchor Configuration for Each Anchor Point

Double Anchor Configuration for Each Anchor Point

Dual Direction Anchor Configuration for Each Anchor Point

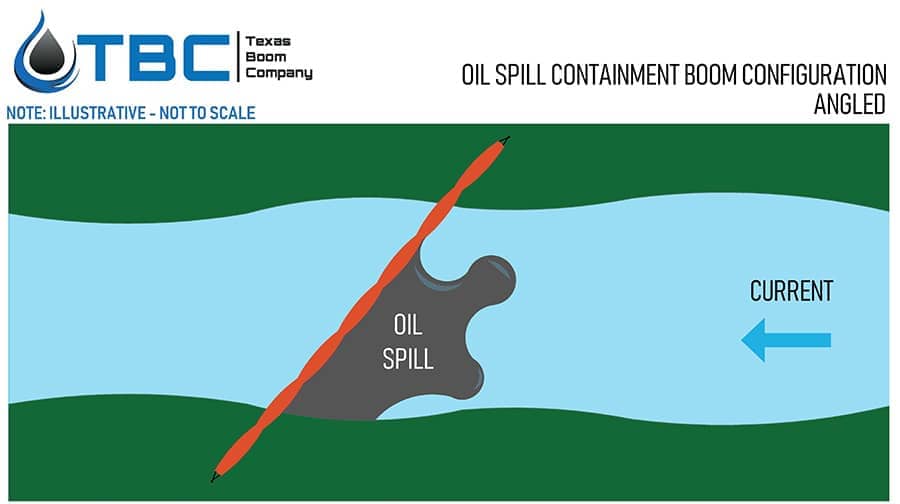

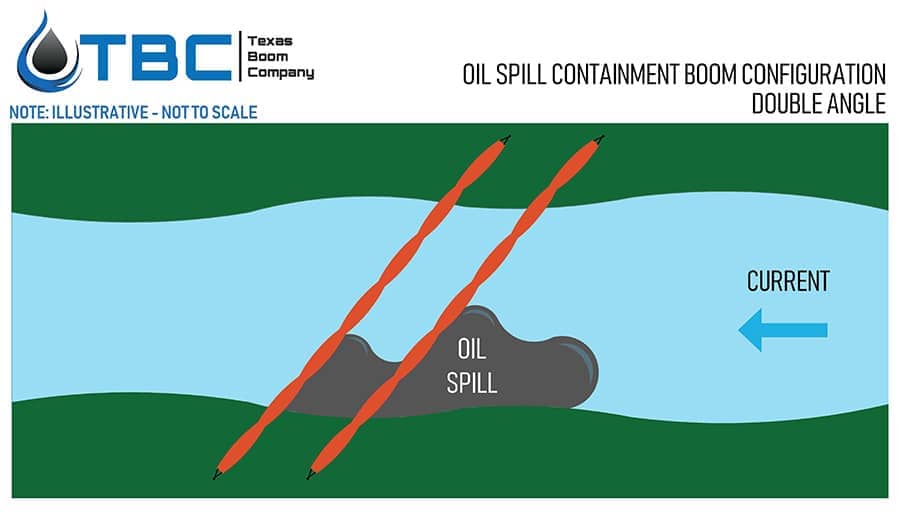

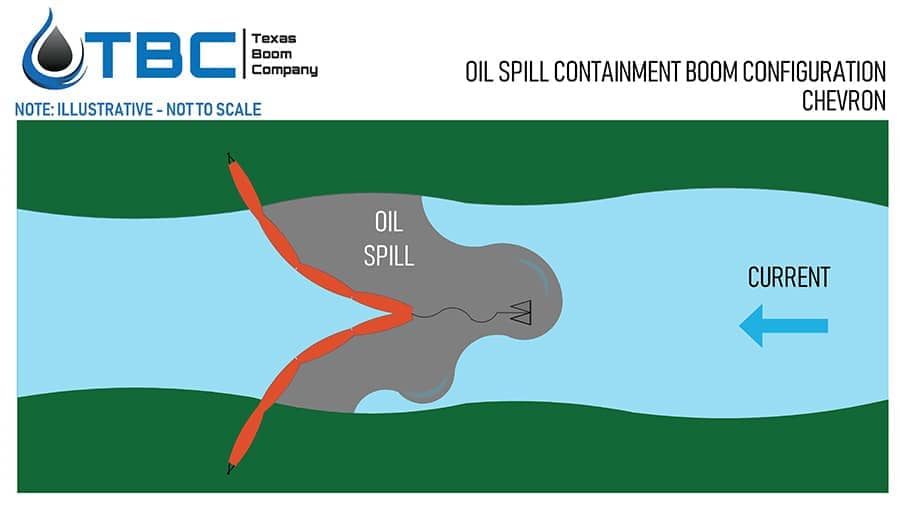

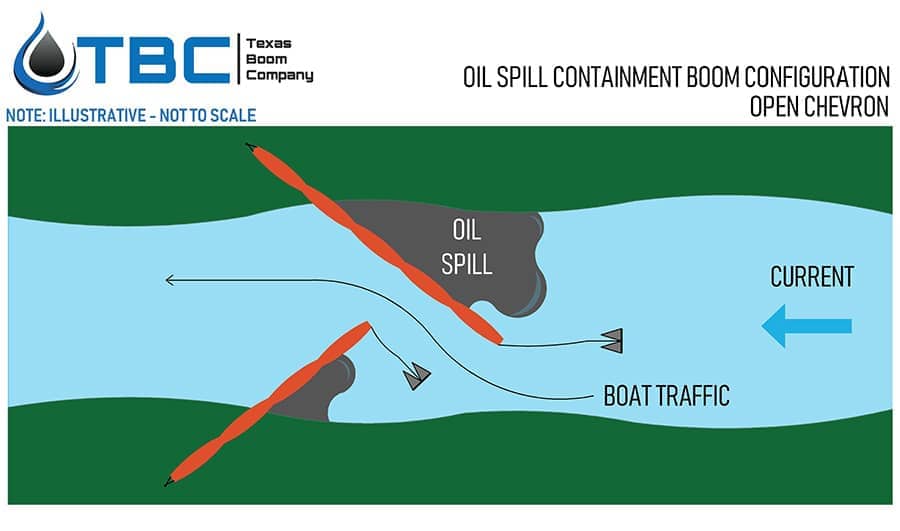

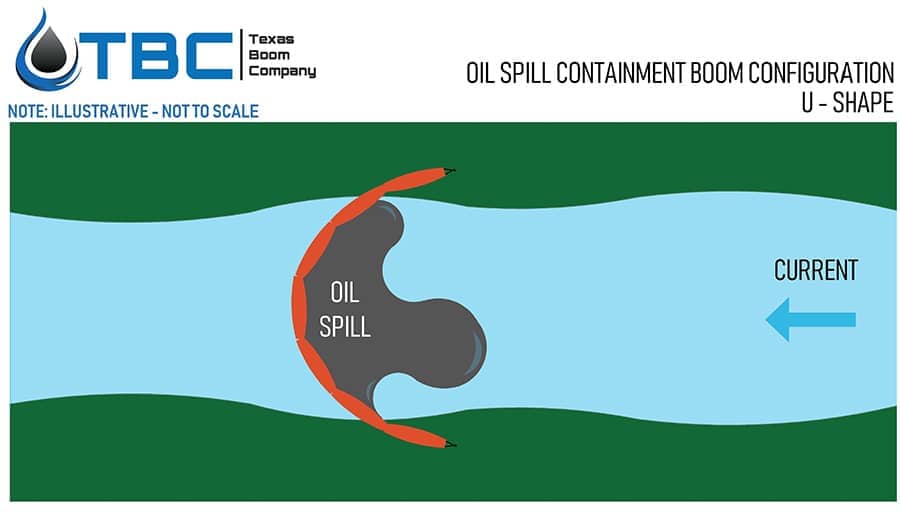

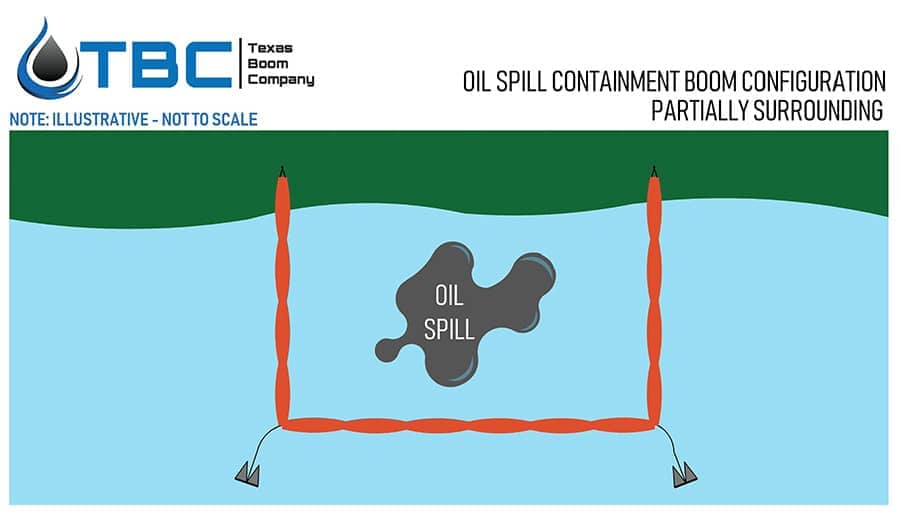

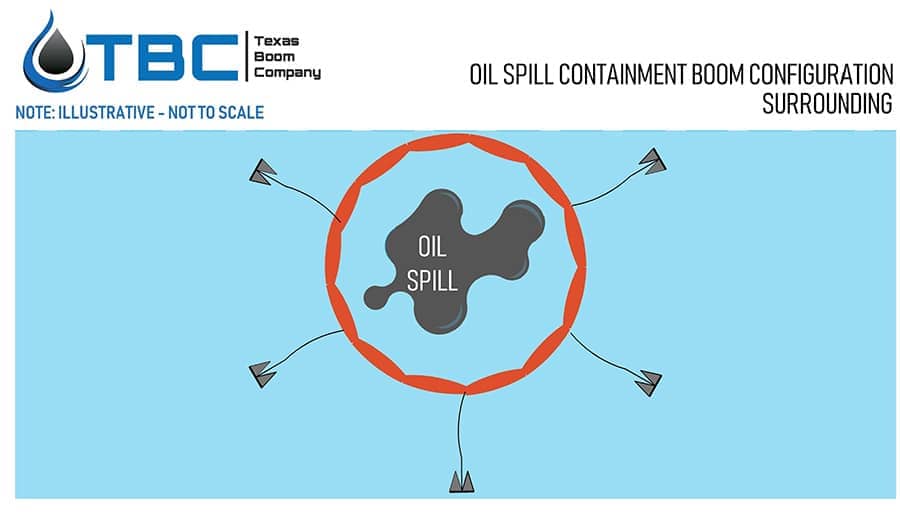

The following diagrams demonstrate a variety of layouts that can be used to deploy oil spill containment boom, depending on the conditions. Tides, currents, wind, waves, and boat traffic must all be considered when deciding upon a containment boom layout. The position of the containment boom can direct oil to a location for collection with a vacuum or skimmer.

Single Angled Containment Boom

Double Angled Containment Boom

Chevron Containment Boom

Open Chevron Containment Boom Layout

U-shaped Containment Boom Layout

Partially Surrounding Containment Boom Layout

Fully Surrounding Containment Boom Layout

A: As our company name indicates, Texas Boom Company does make containment boom. In addition, TBC manufactures turbidity curtains, collapsible fabric tanks, secondary containment berms and other custom products requiring RF welding. In addition, we offer sorbent boom, pads, and rolls, oil skimmers and kits, boom reels, anchors and buoys, and diesel trailers. We also offer expert advice to help ensure you have the right solution for your project.

A: Texas Boom operates in Houston, TX but ships products all over the world.

A: Yes, TBC can fabricate relevant products to a customer’s exact specifications. We can also provide expert advice if there are questions about those specifications.

A: Since 1986, Texas Boom has been fabricating oil containment boom, silt curtains, and bladder tanks. The company has operated under three ownership groups over that time, and is hitting its stride in driving growth for the future.

A: Yes, Texas Boom can fabricate products to a customer’s exact specifications, including labeling. This allows the custom to resell a product under their own brand name.

A: TBC manufactures conventional boom, river boom, permanent (fence) boom, inflatable boom and shore barrier. These boom types come in various sizes and colors.

A: Location, currents, tides, and wind all must be taken into consideration when selecting a particular oil spill containment boom for purchase. If you aren’t sure which boom you need, it is strongly suggested that you consult with one of our expert advisors to help you choose the product that is right for your purchase.

A: TBC does not provide oil spill response services. We work with customers to provide them with the oil containment boom that they need, but do not do the installation.

A: Texas Boom does not manufacture fire boom, which is used to contain oil spills and allow them to be burned off at the spill location. This is a specialty product that few suppliers fabricate.

A: There are several factors that we believe differentiate Texas Boom Company from the competition. First, we utilize RF welds on all of our products. This technology consistently provides the strongest welds that adhere the fabrics used. Next, we use top grade materials to fabricate our products. From the fabric to the hardware, you can be confident our components will not lead to product failure. All components are not created equal. We also offer the ability to quickly and economically fabricate to your exact specifications? Regardless of the fabric weight or color, boom height or length, floatation or ballast required, Texas Boom Company has you covered. And if you need it fast, we stock product for quick response.

A: Yes, TBC offers Boom Reels that are typically used to store and deploy inflatable boom. We can offer stationary boom reel racks, or provide reels that are mounted on trailers to provide ease of mobility. Contact us to discuss your specific boom reel needs.

A: Typically, the boom is either tied off to piling or stakes when deployed near shore. If there are not stationary sites to tie off to, then anchor kits are used to hold the oil spill boom in position. It is important to consider current, tides, wind and waves, as well as the need to not impede boat traffic, when planning the deployment. More information on installation and anchoring can be found here.

A: TBC can provide storage containers to transport and store the boom in when not in use. Shipping containers are often used for this purpose, but other options are available as well. It is important to keep boom clean while limiting exposure to the sun (UV) and rodents during storage. This will significantly increase the life of the boom.

A: If the oil containment boom has been exposed to oil, it can be cleaned. However, the cost to adequately perform this task often exceeds to expense of properly disposing of the soiled boom and replacing it.

A: Small rips, tears, or punctures can be repaired using a Texas Boom Repair Kit. These type repairs are limited to small ruptures.

A: Yes, the boom sections have aluminum connectors and pins on each end that allow the sections to be connected end to end to form long continuous runs of boom. Connecting these sections together is easy to do and forms a secure link.

A: The lengths offered are those typically requested. Buying shorter sections of boom increases the cost due to more frequent aluminum end connectors. Purchasing longer sections of containment boom results in heavier weights that make it more difficult to handle the boom during installation, retrieval, cleaning, and storage. The 50 foot and 100 foot sections are the optimal lengths for most applications, but custom lengths are available upon request.

A: We typically stock TBC containment boom and fabric in international orange, but we often also use yellow when requested by customers. Other colors may be used, depending on fabric availability from our suppliers. Different weight PVC fabrics can be used to manage a balance between cost and durability. The fabrics used are selected for their proven durability, creating value for our customers.

A: TBC manufactures a range of turbidity curtains, typically classified as Type 1, Type 2 and Type 3. There may be specific requirements for curtains within each of these classes per local, state, or federal DOT standards. These turbidity curtains all come in various sizes (lengths and heights). Common fabric colors utilized include international orange or yellow for the floats, and orange, yellow or black for the skirts. Skirts can be fabricated using permeable or impermeable fabrics. TBC can help you make the right selection amongst these options.

A: Location, currents, tides, and wind all must be taken into consideration when selecting a particular silt curtain for purchase. In addition, you must consider the depth of the water were the curtain will be deployed, as well as the contour of the bottom. Typically, you want the bottom of the skirt to be suspended one foot above the bottom. The skirts can be tapered to follow the appropriate depth. Furling lines (optional add on) can also be utilized to adjust the skirt height as needed. If you aren’t sure which boom you need, it is strongly suggested that you consult with one of our expert advisors to help you choose the product that is right for your purchase.

A: TBC does not provide installation services. We work with customers to provide them with the silt curtain that they need, but do not do the installation.

A: There are several factors that we believe differentiate Texas Boom Company from the competition. First, we utilize RF welds on all of our products. This technology consistently provides the strongest welds that adhere the fabrics used. Next, we use top grade materials to fabricate our products. From the fabric to the hardware, you can be confident our components will not lead to product failure. All components are not created equal. We also offer the ability to quickly and economically fabricate to your exact specifications? Regardless of the fabric weight or color, curtain height or length, floatation or ballast required, Texas Boom Company has you covered. And if you need it fast, we stock product for quick response.

A: Typically, the turbidity curtains are either tied off to piling or stakes when deployed near shore. If there are not stationary sites to tie off to, then anchor kits are used to hold the turbidity curtains in position. It is important to consider current, tides, wind and waves, as well as the need to not impede boat traffic, when planning the deployment. More information on installation and anchoring can be found here.

A: TBC can provide storage containers to transport and store the turbidity curtains when not in use. Shipping containers are often used for this purpose, but other options are available as well. It is important to keep the turbidity curtains clean while limiting exposure to the sun (UV) and rodents during storage. This will significantly increase the life of the curtain.

A: Yes. Because turbidity curtains are typically only exposed to silt and sediment, they can be hosed off prior to storage and reused. Debris and mishandling can cause damage to silt curtains, so it is advised to frequently inspect them during and after use.

A: Small rips, tears, or punctures can be repaired using a Texas Boom Repair Kit. These type repairs are limited to small ruptures.

A: Yes, the turbidity curtain sections have different connection mechanisms, depending the on the type purchased. Type 1 curtains typically do not have connector plates – the tension cables and ballast chains are connected end to end with shackles, and the grommets along the end seams are connected using rope, strong zip ties, or stainless steel nuts and bolts. Type 2 and Type 3 turbidity curtains feature connector plates at the top and bottom, and the grommets are connected as described above.

A: The lengths offered are those typically requested. Buying shorter sections of turbidity curtains increases the cost due to more frequent end connectors. Purchasing longer sections of turbidity curtains results in heavier weights that make it more difficult to handle during installation, retrieval, cleaning, and storage. The 50 foot and 100 foot sections are the optimal lengths for most applications, but custom lengths are available upon request.

A: We typically stock TBC turbidity curtains and fabric in international orange, but we often also use yellow when requested by customers. Other colors may be used, depending on fabric availability from our suppliers. Different weight PVC fabrics can be used to manage a balance between cost and durability. The fabrics used are selected for their proven durability, creating value for our customers.

A: Permeable skirts use a geotextile fabric that allows water to pass through while filtering any suspended particles like silt or other run off. These are typically deployed when there is a current or notable water flow in the area to reduce the pressure on the curtain. Permeable skirts are made with a solid fabric that does not allow any water to flow through. These are typically used in calm and protected waters.

A: These tanks are fabric tanks made by welding the outer edges of two fabric sheets. When full, these tanks look like a pillow. The fabric is heavy duty industrial fabric that allows for strong welds to form seams, but when empty, the tanks can be rolled or folded to take up far less space than a traditional rigid tank. A range of valves can be added to meet required specifications. These tanks are also referred to as bladder tanks, and are can be used for a wide range of applications, including fuel, water, potable water, and chemicals.

A: An onion tank is an open topped tank, named as such because it resembles and onion or pumpkin when filled. These tanks are constructed with heavy duty industrial fabric and lay flat when empty. Because the collar around the opening is built with floatation, the tank rises as the tank fills. These tanks are a great option for economical and mobile liquid storage.

A: An onion tank is an open topped tank, named as such because it resembles and onion or pumpkin when filled. These tanks are constructed with heavy duty industrial fabric and lay flat when empty. Because the collar around the opening is built with floatation, the tank rises as the tank fills. These tanks are a great option for economical and mobile liquid storage.

A: We recommend specifying a bladder as being used for potable water, as it requires a different fabric than a normal bladder tank. TBC usually makes these in a blue fabric to identify them as potable water tanks.

A: TBC can fabricate most any tank design. This includes the type and size of valves and adapters needed for a specific application. Please provide us with your exact specifications or general preferences and we will quickly provide you with pricing and lead times required to deliver your tank.

A: Bladders can also be air filled as well. TBC has constructed air filled bladders to be used as pipe stoppers, floatation devices, and lift bags as well.

A: While the bottom of these secondary containment berms may appear similar to a heavy duty tarp, the additional of the various types of side walls serve to make these a reliable means to contain any type liquids. That means that the berms offer a high capacity capability to keep spills or wash down liquids from entering soil or nearby drains.

A: The drive on berms have walls filled with open cell foam. This allows them to be crushed while immediately regaining their form. Other berms feature inflatable side walls, while other secondary containment berms offer rigid frames to support the wall flaps of the berm. The specifics of the application dictate which is best suited to meet your needs.

A: A blower is typically suitable to quickly and easily inflate the side walls of a berm. Leaf blowers make excellent inflation tools. All that is required is a properly sized tube to connect the blower tube to the inflation valve.

A: The side walls of the drive on berms are designed to allow vehicles and equipment to roll over them without damaging them. The foam inside the walls can be crushed, but will immediately regain its original shape to contain liquids.

A: TBC can coordinate with customers to arrange LTL service within the continental US. We can also help to arrange global shipping options to deliver product anywhere in the world.

A: These type products are carefully folded and then strapped into manageable sized bundles. These bundles are then stacked on pallets and then wrapped and strapped again to provide stable bundles that can easily be handled with fork lifts. At additional cost, TBC can provide storage boxes and/or shipping containers to provide protection and storage for the boom during and after transport.

A: The customer is responsible for all shipping charges, taxes, duties and tariffs that may be associated with a given shipment. We can ship to customers using their own accounts, including Fedex, UPS and LTL carriers.

A: For small products, we can sometimes ship via either carrier in order to minimize shipping costs. Viable options are offered to customers for consideration.

21401 Park Row Drive Suite #340

Katy, TX 77449

Local: (281) 441-2002

Toll Free: (844) 444-8144