When it comes to construction, dredging, or environmental projects near water bodies, controlling water quality is of paramount importance. Turbidity—the cloudiness or haziness in water caused by suspended solids like silt, sediment, and pollutants—can have detrimental effects on aquatic ecosystems, water clarity, and overall water quality. Turbidity curtains are an essential tool used to address this issue, and Texas Boom offers high-quality, reliable turbidity curtains designed to help manage water pollution and sediment control during various aquatic operations.

What Are Turbidity Curtains?

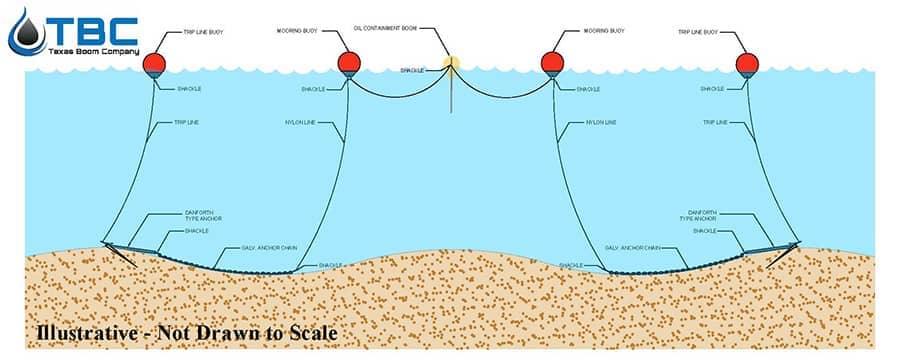

Turbidity curtains, also known as silt curtains or sediment barriers, are floating barriers designed to contain suspended sediments or pollutants within a defined area of water. These curtains are commonly used during activities like construction, dredging, and shoreline restoration, where sediment disturbance can negatively impact water quality. They work by trapping suspended particles and preventing them from dispersing into the surrounding water.

These curtains are typically made from durable, permeable materials that allow water to flow through but prevent the passage of suspended particles. The design often includes a weighted bottom to ensure the curtain stays anchored and upright, providing a physical barrier between the disturbed area and the rest of the water body.

Why Are Turbidity Curtains Important?

Turbidity curtains are crucial for several reasons, especially in maintaining water quality during construction or environmental remediation projects near water:

Sediment Containment: Construction and dredging activities can stir up large amounts of sediment, which can spread throughout the water. Excess sediment can smother aquatic habitats, harm fish populations, and reduce the clarity of the water. Turbidity curtains keep sediment contained within a specific area, protecting surrounding water bodies.

Pollution Control: In addition to sediment, turbidity curtains can help contain pollutants such as oils, chemicals, and other contaminants that might be disturbed during construction activities. By preventing the spread of these pollutants, turbidity curtains help protect sensitive aquatic ecosystems.

Regulatory Compliance: Many environmental regulations require construction projects near water to take measures to control sedimentation and maintain water quality. Texas Boom’s turbidity curtains help ensure compliance with these regulations, reducing the risk of fines or project delays.

Protection of Aquatic Life: Suspended sediment can harm aquatic life in several ways. It can block sunlight from reaching underwater plants, smother fish eggs, and disrupt the feeding and breathing of aquatic organisms. By using turbidity curtains, businesses help safeguard the health and biodiversity of the aquatic ecosystem.

Key Benefits of Turbidity Curtains from Texas Boom

Texas Boom provides high-quality turbidity curtains designed to effectively manage sediment control and protect water quality during various projects. Here are some of the key benefits of using Texas Boom's turbidity curtains:

1. Effective Sediment and Pollution Control

The primary purpose of turbidity curtains is to prevent the spread of suspended sediment and pollutants in water bodies. Texas Boom’s turbidity curtains are designed to be highly effective in containing sediment stirred up by construction or dredging activities, ensuring that only the intended area is affected. These curtains are made from strong, permeable fabrics that prevent fine particles from escaping while allowing water to flow through.

This effective sediment containment prevents issues such as reduced water clarity, which can lead to oxygen depletion and negatively affect aquatic life. Texas Boom’s curtains help keep surrounding water bodies clean and safe.

2. Customization for Specific Needs

Not all water bodies and construction projects are the same, and neither are the challenges they pose. Texas Boom offers turbidity curtains that can be customized to meet the specific needs of each project. Whether you are working in calm, shallow waters or fast-moving currents, Texas Boom can tailor the curtain size, material, and design to ensure optimal performance.

Customizable options include varying depths, lengths, and the choice of materials that are resistant to UV rays, chemical exposure, and rough conditions. With Texas Boom's tailored solutions, you can be sure that the turbidity curtain will work efficiently, no matter the water environment.

3. Easy Installation and Maintenance

Texas Boom’s turbidity curtains are designed for easy installation and removal. The lightweight materials and simple setup process allow for quick deployment on construction sites, ensuring minimal disruption to the project timeline. Whether you're dealing with a small residential construction project or a large industrial dredging operation, Texas Boom’s turbidity curtains can be set up quickly and efficiently.

In addition to their easy installation, these curtains are built for durability, requiring minimal maintenance during use. The durable fabrics resist wear and tear, UV degradation, and physical damage from water, ensuring that the curtains continue to perform effectively throughout the project.

4. Durability and Long-Term Use

Texas Boom’s turbidity curtains are made from high-quality materials that are designed to withstand harsh water conditions. Their curtains are built to last, ensuring long-term use on multiple projects. The materials are engineered to resist the effects of UV rays, saltwater exposure, and abrasion, making them ideal for both freshwater and marine environments.

Thanks to their durability, these turbidity curtains can be reused across various projects, providing a cost-effective solution for businesses that need to protect water quality over time. This long lifespan reduces the need for frequent replacements and provides excellent value.

5. Regulatory Compliance

Environmental regulations are strict when it comes to sediment control and water quality management, especially for projects near water bodies. Texas Boom’s turbidity curtains are designed to meet or exceed regulatory standards for sediment containment and water protection.

By using Texas Boom’s turbidity curtains, businesses can demonstrate their commitment to environmental responsibility and ensure compliance with local, state, and federal environmental regulations. This proactive approach can help avoid costly fines, delays, and legal issues associated with non-compliance.

6. Eco-Friendly Water Management Solution

Turbidity curtains are an eco-friendly solution for managing sediment and pollutants in water bodies. Rather than relying on harmful chemicals or heavy machinery, turbidity curtains provide a natural and passive means of controlling water contamination. By using these curtains, businesses contribute to the preservation of local ecosystems and biodiversity.

By containing sediment and pollutants, turbidity curtains help maintain the natural balance of aquatic environments, promoting cleaner, healthier waterways for wildlife and local communities.

Applications of Turbidity Curtains

Turbidity curtains from Texas Boom can be used in a wide range of applications, including:

- Dredging Projects: When dredging sediments from the bottom of rivers, lakes, or harbors, turbidity curtains help contain disturbed material and prevent it from spreading through the water column.

- Construction and Development: During construction near water bodies—such as building piers, docks, or marinas—turbidity curtains prevent sediment from being released into surrounding waters, ensuring minimal impact on local ecosystems.

- Environmental Remediation Projects: In cases where pollutants need to be contained during shoreline restoration or wetland rehabilitation, turbidity curtains help control sediment and chemical dispersal, aiding in the remediation process.

- Stormwater Runoff Control: In stormwater management, turbidity curtains can be deployed to prevent the flow of sediment and pollutants from stormwater runoff into nearby water bodies.

Conclusion

Turbidity curtains from Texas Boom are a reliable, efficient, and eco-friendly solution for protecting water quality during construction, dredging, and environmental remediation projects. By effectively containing sediment and pollutants, these curtains help preserve aquatic ecosystems, ensure regulatory compliance, and maintain the clarity and health of local waterways.

With customizable options, easy installation, and long-term durability, Texas Boom’s turbidity curtains offer a cost-effective solution that helps businesses meet their environmental responsibilities while protecting the natural environment. Whether you are working in a river, lake, harbor, or nearshore area, Texas Boom provides the tools you need to maintain clean and safe waterways for both the environment and the communities that rely on them.